A Comprehensive Guide to Finite Element Analysis in Modern Engineering Services

Contents |

[edit] The role of finite element analysis (FEA)

Finite element analysis (FEA) has revolutionised the engineering landscape, transforming how we design, analyse, and optimise complex structures and systems. It is no exaggeration to say that FEA has become an indispensable tool in modern engineering services, enabling us to push the boundaries of innovation and achieve remarkable feats of construction and design.

This comprehensive guide dives deep into the world of Finite element analysis, exploring its theoretical underpinnings, practical applications, and transformative impact on various engineering disciplines. We'll equip you with the knowledge to understand how FEA works, appreciate its benefits, and harness its power to elevate your engineering endeavours.

[edit] Demystifying the fundamentals of FEA

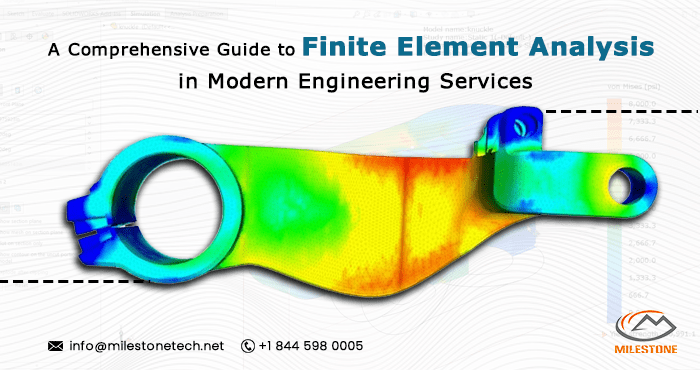

At its core, FEA is a computational technique for approximating the behaviour of complex systems by dividing them into smaller, simpler elements. These elements, often geometric shapes like tetrahedrons, hexahedrons, or wedges, are interconnected to form a discretised mesh that represents the entire system. Each element is assigned material properties, such as elasticity, density, and thermal conductivity, along with the forces and constraints it experiences.

By applying the principles of mechanics and mathematics to each element, FEA software can calculate its deformations, stresses, strains, and other relevant engineering quantities. The combined responses of all the elements are then assembled to provide a comprehensive picture of the system's overall behaviour under the applied loads and conditions.

[edit] Applications of FEA and its power

The versatility of FEA extends far beyond simple structural analysis. It finds applications in a vast array of engineering disciplines, including:

- Civil Engineering: FEA helps optimise the design of bridges, buildings, dams, and other structures, ensuring their safety, stability, and resilience under diverse loading conditions like wind, earthquakes, and dead loads.

- Mechanical Engineering: FEA plays a crucial role in designing and analysing machine components, power trains, and other mechanical systems, predicting their performance, fatigue life, and potential failure points.

- Thermal Analysis: Thermal analysis is an analytical technique whereby changes in the physical state of a substance or its products are evaluated as a function of temperature and time (in some cases).

- Aerospace Engineering: From aircraft wings and fuselages to rocket engines and spacecraft structures, FEA is instrumental in ensuring the structural integrity and aerodynamic performance of aerospace vehicles.

- Biomedical Engineering: FEA helps model and analyse the complex biomechanics of human tissues, bones, and joints, aiding in the development of prosthetics, implants, and surgical procedures.

- Automotive Engineering: FEA optimises the design of car chassis, engine components, and safety systems, contributing to lighter, safer, and more fuel-efficient vehicles.

These are just a few examples, and the applications of FEA are constantly expanding as engineers leverage its power to tackle ever-more complex challenges.

[edit] The FEA workflow, from model to insight

Performing an FEA analysis typically involves the following steps:

- Geometry creation: This involves building a 3D model of the system under study using CAD software or directly within the FEA software.

- Meshing: The model is then discretised into a mesh of finite elements, with the element size and type depending on the desired level of accuracy and computational efficiency.

- Material properties assignment: The material properties of each element, such as Young's modulus, Density, Poisson's ratio, and yield strength, are defined based on the actual material used in the system.

- Loads and constraints application: The various forces, pressures, and displacements acting on the system are applied to the relevant elements or nodes.

- Solver execution: The FEA software then solves the system of equations governing the behaviour of each element, considering the interactions between them.

- Post-processing: The results of the analysis are visualised and analysed, often using colour-coded stress and strain plots, animation of deformations, and other graphical representations.

[edit] The FEA advantage

Why choose to use this powerful tool?

FEA offers a multitude of benefits over traditional engineering methods, such as:

- Reduced reliance on physical prototypes: FEA allows virtual testing of designs, minimising the need for expensive and time-consuming physical prototypes.

- Enhanced design optimisation: By iteratively analysing and refining designs within the virtual environment, engineers can optimise performance, minimise weight, and reduce material usage.

- Improved safety and reliability: FEA helps identify potential failure points and weaknesses in a design, enabling engineers to make necessary modifications before real-world deployment.

- Deeper understanding of complex phenomena: FEA provides valuable insights into the behaviour of materials and structures under various loading conditions, leading to a more profound understanding of engineering principles.

- Accelerated innovation: By streamlining the design and analysis process, FEA paves the way for faster innovation and shorter product

[edit] Conclusion

In the rapidly evolving landscape of engineering services, Finite Element Analysis stands as a cornerstone for informed decision-making. Its ability to predict and analyse the behaviour of structures and components under different conditions empowers engineers to design with confidence and precision. As technology continues to advance, the integration of FEA with tools like Building Information Modeling will further enhance the capabilities of engineering professionals, ensuring that the structures of tomorrow are not only functional and safe but also optimised for efficiency and sustainability.

--Engineering Design & BIM Services

[edit] Related articles on Designing Buildings

Featured articles and news

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this.